Repairability, Update and Ease of Maintenance

Textile products must be designed to be easily repairable. This includes:

Robust seams that are easy to unpick and sew back.

Detachable and interchangeable parts (e.g., buttons, zippers).

Clear instructions for the consumer on how to extend the life of products (repairs, care, suitable washing).

A design that facilitates updates or customization to extend the product's life and meet changing needs.

Reduction of environmental and carbon footprint

Manufacturers must minimize the environmental footprint of the product throughout its life cycle. This includes measuring and reducing the carbon footprint, from raw material extraction to production, transportation, use, and end of life. The ESPR also requires the integration of cleaner technologies and energy-efficient solutions.

Reusability

Textile items must be reusable, either by consumers directly or through second-hand or refurbishment initiatives. Products should be easily redistributable or reused without undergoing major changes.

Waste management and waste generation prevention

Products must be designed to minimize waste production throughout their lifecycle. This includes optimizing production to reduce fabric scraps and using reusable or biodegradable materials for packaging. The goal is to encourage a circular economy where end-of-life products are reused, repaired, or recycled rather than discarded.

Sustainability and Reliability

Products must be designed to have a long lifespan and withstand prolonged use. For textiles, this means they must be sturdy, tear-resistant, wear-resistant, and capable of maintaining their appearance and properties (color, texture) even after several wash cycles.

Ease of remanufacturing and recycling

Textiles must be designed to facilitate remanufacturing and recycling at the end of their life. This means:

Using mono-material fibers or easily separable fiber blends.

Clearly labeling textiles to indicate their materials and recycling potential.

Working with recycling infrastructures to ensure that used textiles can be transformed into new raw materials.

Content made from recycled materials

The ESCP encourages the use of recycled materials in product design. Brands will need to incorporate a significant proportion of recycled fibers, for example, by using materials such as recycled polyester or recycled cotton, without compromising the quality or durability of the products.

Energy efficiency and resource use during production

Textiles must be made while minimizing the use of natural resources and energy at every stage of the life cycle. Manufacturers must optimize production processes to:

Reduce carbon footprint and greenhouse gas emissions.

Use less water and energy.

Optimize raw materials to limit losses and waste.

Presence of substances of concern

Textile products must be free from or contain a minimum of harmful substances for human health and the environment. This includes the elimination or reduction of the use of toxic chemicals, such as azo dyes, brominated flame retardants, and phthalates. Companies must follow the lists of regulated substances, such as the REACH Regulation in Europe, and provide clear information about the chemical composition of the products.

Textiles must be accompanied by a Digital Product Passport (DPP), a digital file that contains crucial information about the product throughout its life cycle. This passport

Traceability

Facilitate the traceability of the materials used as well as their origin and carbon impact

Sustainability

Contains information about sustainability and end-of-life options (repair, recycling).

Technology

Use QR codes or NFC tags to provide quick and secure access to this data.

The Digital Product Passport:

from a regulatory challenge to a growth opportunity

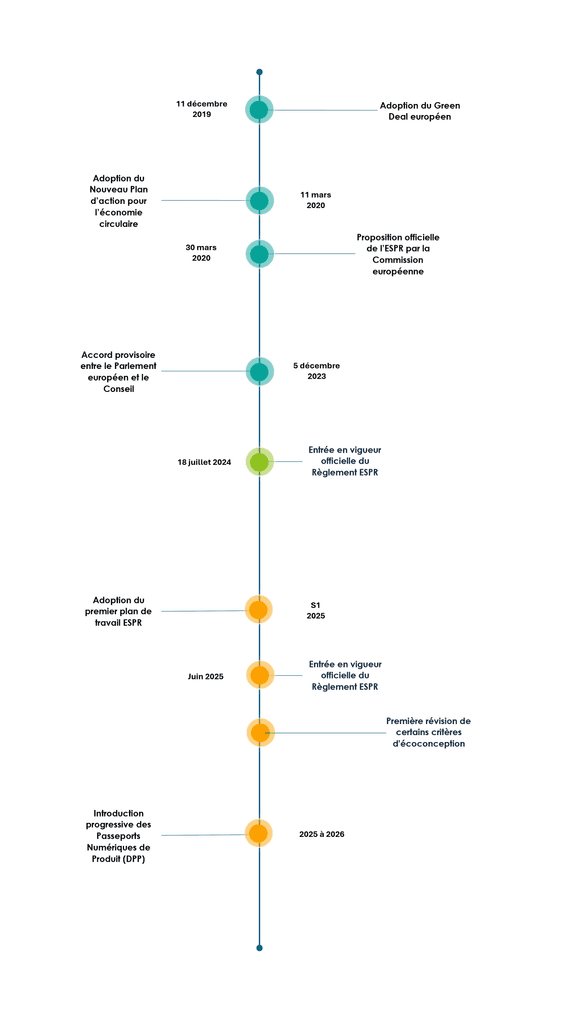

Implementation schedule of the ESPR

This regulation aims to make products more repairable, durable, and recyclable, with a positive impact on reducing waste and carbon footprint. The deployment of the ESPR measures will begin in July 2024 and will extend until 2026, with a specific action plan for each product category (textiles, electronics, steel, etc.). This timeline will allow companies to gradually comply with the new EU requirements, thereby reinforcing the transition to a circular economy and product sustainability.

To learn more

Document

Regulation (EU) 2024/1781 of the European Parliament and of the Council of June 13, 2024

Press release

Le Conseil et le Parlement concluent un accord provisoire sur le règlement sur l'écoconception.

Press release

Ecodesign: new EU rules to make sustainable products the norm